Since its founding, UCC has been proactive about developing revolutionary new technologies and deploying the latest advancements to produce even more delicious coffee.

We succeeded in developing the world's first canned coffee beverage in 1969, creating the basis for today's canned coffee market. In 1970, we completed the first fully-automated Japanese plant packing ground coffee, utilizing vacuum packing to deliver fresh, aromatic coffee to consumers. In 1996, we developed the Super Aroma System, a process by which coffee is ground and packed without exposing it to the air, sealing the aroma in and achieving unprecedented fragrance.

We also employ the Aroma Freezing Process (Japanese patent no. 3617906), whereby freshly roasted beans are immediately frozen at a temperature of -2℃ to seal in the aroma. In addition, other producers normally blend the beans before roasting them, but we perform standalone roasting, whereby different types of bean are roasted individually before the final blend. This draws out the particularities of each producing region's beans. These and other unique techniques are part of our commitment to quality.

Moreover, our TTND (Japanese patent no. 3057026) technique achieves canned coffee that is flavorful and with a sharp aftertaste, while our Shiga Plant features the beverage industry's fastest recappable canning line and sterilized plastic bottle capping system.

The UCC Rokko Island Factory in the city of Kobe, Hyogo, one of our key factories manufacturing coffee for brewing

Aromaster roasting machine

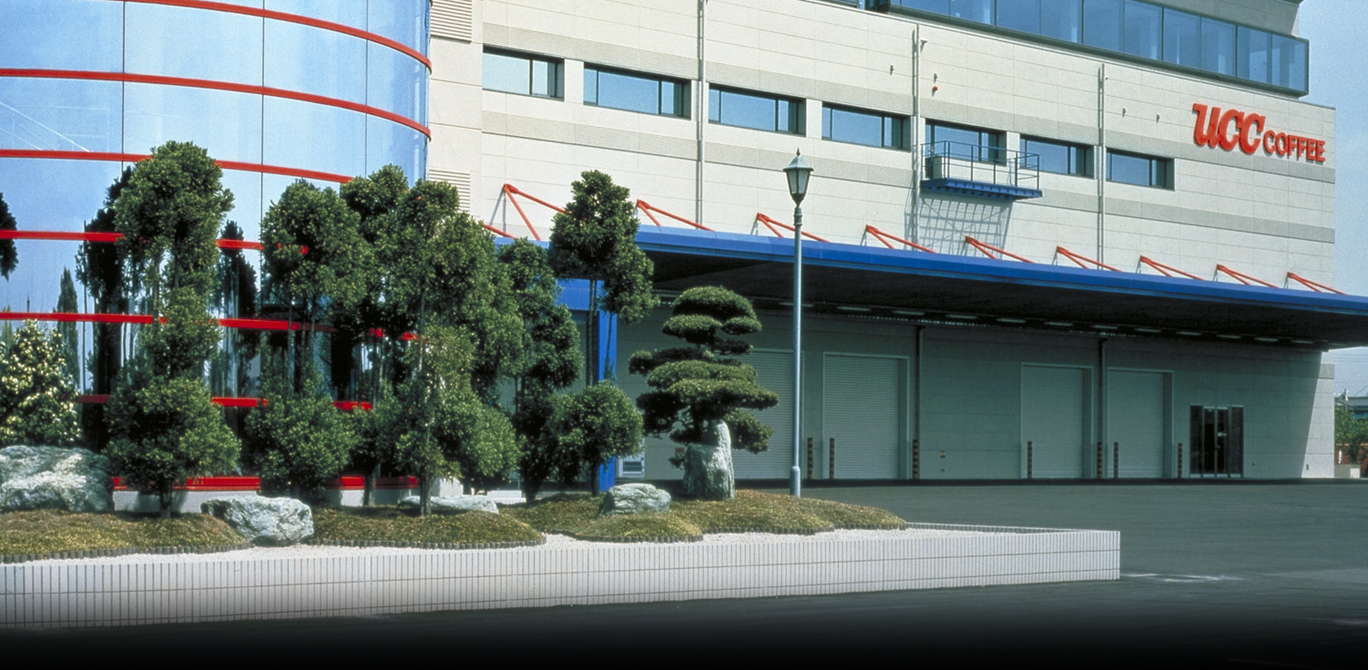

The UCC Shiga Factory, equipped with the beverage industry’s fastest production line for cans with caps and a plastic bottle production line incorporating the industry’s most up-to-date sterile filling system

UCC continues to employ the latest technologies in order to deliver you an uncompromisingly delicious cup of coffee.

Cloth filters made from flannel are known to tease out the taste of coffee better. This same concept is also used by artisans when producing a fine brew.Clients came to us with a demanding request: could we automate the process of flannel dripped coffee and bring this unique taste to more people? The result is our flannel drip machine.

This device replicates the skill of an artisan barista, delivering the supreme quality of cloth dripped coffee in a stable format.

A new kind of iced coffee delivered through UCC's own dispensers. The fine foam almost resembles mousse, and the taste is unbeatably smooth.

As soon as you take a sip, you will be amazed at the full-bodied taste. Experience the ultimate cup of iced coffee.

How to provide a delicious cup of coffee in conditions where an open flame cannot be used? We saw this puzzle as a new challenge for us.

We developed the Light Siphon, a coffee siphon that does not require the cumbersome use of alcohol lamps and other fuel sources.

A high-emitting halogen bulb provides not only stable heat, but unique illumination, producing a one-of-a-kind performance.

Using a specialized "twist shower nozzle," this apparatus achieves an even hand drip by way of a drip pot with a narrow spout.

This new style of hand drip machine allows the user to carefully control the timing with which hot water is added, as well as use a steam function to keep the coffee grounds hot while dripping.